Leidenschaft für Geräte und Komponenten.

Division Appliances.

(OEM-)Komplettgeräten und Baugruppen.

Gemäß den individuellen Anforderungen unserer Kunden entwickeln und fertigen wir als ODM- und OEM-Gerätehersteller an unseren Standorten komplette Produkte mit hohen Ansprüchen an Design, Funktionalität und entsprechender Leistungselektronik in Serie und übernehmen zudem die Prozesse der Zertifizierung, Verpackungsgestaltung und Logistik.

Division Ventilation & Surfaces.

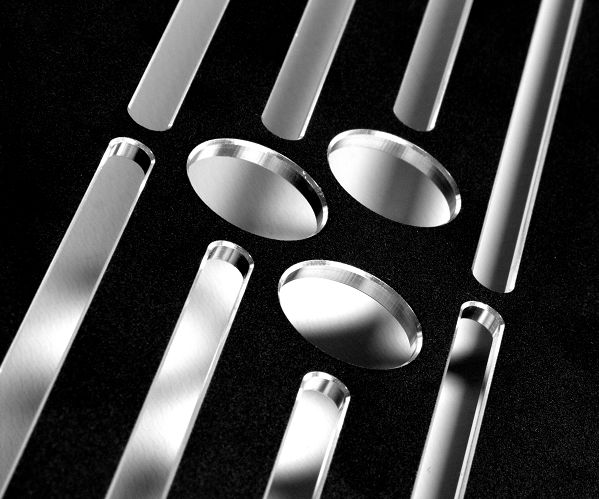

Mit unseren Möglichkeiten in der Verarbeitung von Aluminium, Blech, Edelstahl und Stahl sowie in der Oberflächenveredelung geben wir Metallen nicht nur eine Form, sondern einen individuellen Charakter.

Darüber hinaus sind wir Ihr Ansprechpartner in der Entwicklung kompletter Gebläsesysteme oder in der leistungsgerechten Optimierung von einzelnen Lüfterkomponenten.

Division Kinematics.

kinematischen Komponenten.

Über unsere Auszugschienen sowie mechanischen und elektromechanischen Scharniere bringen wir Bewegung in zahlreiche Anwendungsgebiete, beispielsweise für das komfortable Sensorik-gesteuerte Öffnen und Schließen von (Backofen-)Türen oder Kühlschränken.

Internationale

Kunden.

Als Systemlieferant beliefern wir Weltmarktführer in den Branchen Hausgeräte, Gastronomie, Automotive, Consumer Goods, Medizintechnik und Bau.

Crossfunktionale Unternehmensgruppe.

Dabei sind wir in den unterschiedlichsten Branchen und für zahlreiche Hersteller aktiv, am Beispiel einer Haushalts- und Industriesimulation:

Breite und Tiefe

in der Fertigung

Produkte

mit Charakter.

Globale Stärke.

Standorte weltweit

Mitarbeitende

Internationale Kunden

m² Produktionsfläche

Innovationen

und News.

frimotion® Scharnier

für Kühlschränke.

Perforierte Oberflächen, die ein „sprechendes“ Metall über integrierte Lichtleiter oder durch die Ansteuerung per Sensorik ermöglichen.

Colorierte Aluminiumoberflächen setzen neue Trends und Akzente in Küchen, Bädern, im Automotive- und Consumer-Bereich. Neben klassischen Farben wie anthrazit, schwarz und Alu natur sind es vor allem trendige Naturtöne oder sogar ausgefallene bunte Oberflächen, die eine neue Kundenzielgruppe erreichen können.

Lean Management steht für die bestmögliche Ausführung aller Prozesse ohne Verschwendung, in Verbindung mit dem Ansatz der kontinuierlichen Verbesserung. Bei Gronbach streben wir stets nach Verbesserung in allem was wir machen. Deshalb wird der Lean Management Gedanke hier gelebt und eingefordert. Gestützt auf die Lean Prinzipien wie Fließen, Takten, und Ziehen gestalten wir unsere Prozesse […]